SAVE WATER 100%

TrumpJet® completely eliminates the use of fresh water or clear filtrate in post dilution of wet end additives, which usually saves 10-18% of the papermill’s total water consumption.

SAVE CHEMICALS 20-60%

With TrumpJet®, chemicals and additives are utilized more efficiently, resulting in a cleaner process, better paper quality, and considerably lower chemical consumption, 20-60%, even more.

SAVE ENERGY

Thanks to water savings made by TrumpJet®, it is no longer needed to heat dilution water to process temperature. The result is considerable reduction of production costs and CO2 emissions.

120 million m3

annual

WATERSAVING

4 million tons

reduced

CO2 emission

680

sold

mixing stations

2001

founded in

What we do

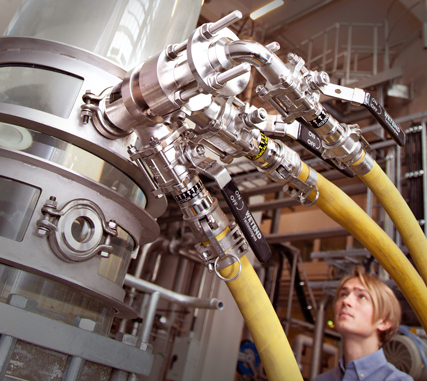

Wetend Technologies Ltd specializes in injection mixing of paper chemicals and wet end additives. Our TrumpJet Flash Mixing technology guarantees fast and uniform chemical mixing that saves water, energy, and chemicals. It also offers many additional benefits that make paper production more efficient and sustainable.

Read more

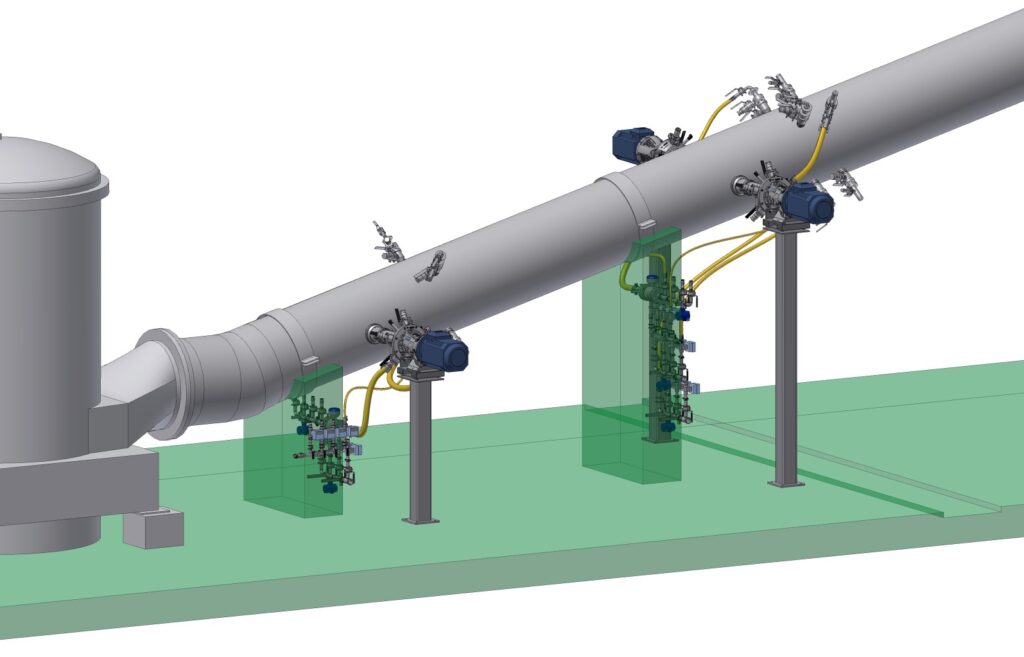

Our products

TrumpJet product portfolio is developed for injection mixing of various types of chemicals and additives into large volume process streams. Mainly our customers are paper and board mills but the technology has been utilized with good results also in water treatment and mining.

Read more

Mill results

Based on the results of over 650 supplied mixing stations, the chemical consumption reduces typically by 20-60 %, water consumption in post dilution by 100%. Optimal chemical mixing location improves runnability and stability of the process, also the wet end chemistry is easier to control.

Read more

Our clients:

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.