Mixing nano- and microfibrillated cellulose in paper production

Trouble-free mixing of MFC and NFC opens new possibilities

Board, paper, and tissue industry has to renew its production and product offering with new bio-based alternatives to meet consumer demands. Wetend Technologies provides innovative solutions for mixing of MFC and NFC, which enable our clients to develop competitive industrial processes and products that meet current expectations and challenges.

Benefits

- New product characteristics

- Optimized MFC/NFC consumption – minimal raw material loss

- Better runnability – fewer sheet defects

Effective mixing of MFC and NFC in a flash of time:

Dosing just before the headbox reduces consumption

After-screen dosing minimizes additive loss

TrumpJet Flash Mixing technology fluidizes microfibrillated cellulose and uniformly mixes it very fast into the paper and cardboard pulp. This allows MFC dosing just before the headbox and prevents recirculation and the expensive additive loss into side flows and rejects.

Resource savings, cleanliness, runnability

Improved MFC retention not only reduces additive consumption, but also the amount of microfibrillated cellulose circulating in white water, which in turn improves cleanliness and minimizes process disruptions.

Optimizing new product characteristics

Homogeneous mixing enables better utilization of the additive and improves product characteristics. For example, if after the installation of a TrumpJet Flash Mixing system, MFC dosage is kept at the same high level as before, then the strength of the resulting sheet significantly increases.

TrumpJet maximizes the benefits from MFC/NFC

Overall, TrumpJet Flash Mixing technology increases the process and end product quality benefits of MFC/NFC, while maintaining process cleanliness, cost efficiency and reduced consumption of chemicals and raw materials.

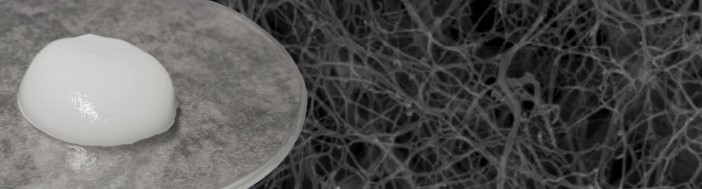

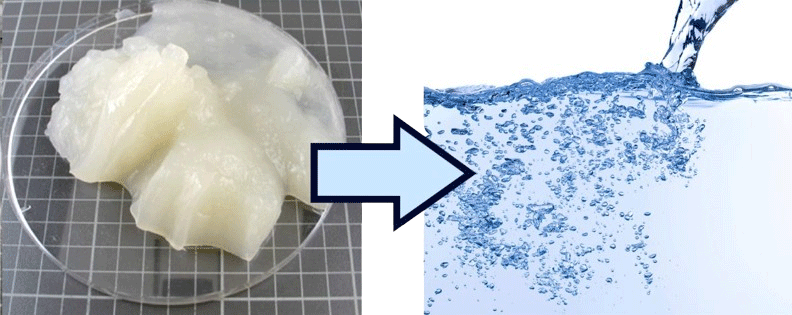

Fluidizing of MFC and NFC

Once the additive enters the TrumpJet mixer, due to the high volume and high velocity of the injection liquid, it is instantly precipitated into filaments, ligaments and finally into drops and droplets inside the fast moving injection stream. The hard-to-mix-gel of MFC/NFC has been fluidized and behaves like low viscose liquid. Then it is mixed in a flash of time into the main process flow.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.