Web Break Eliminator

A simple way to improve runnability and sheet quality

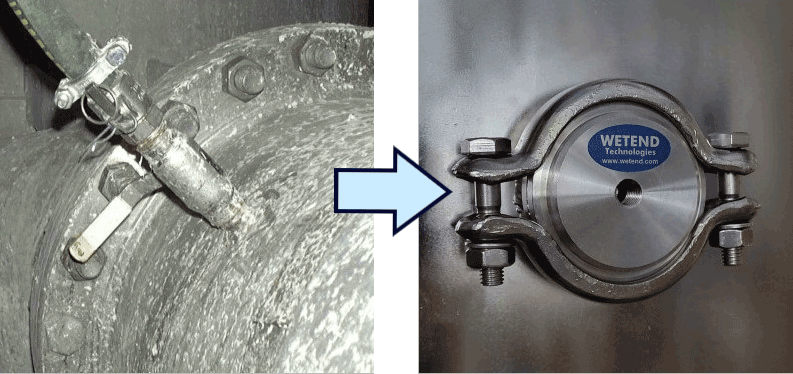

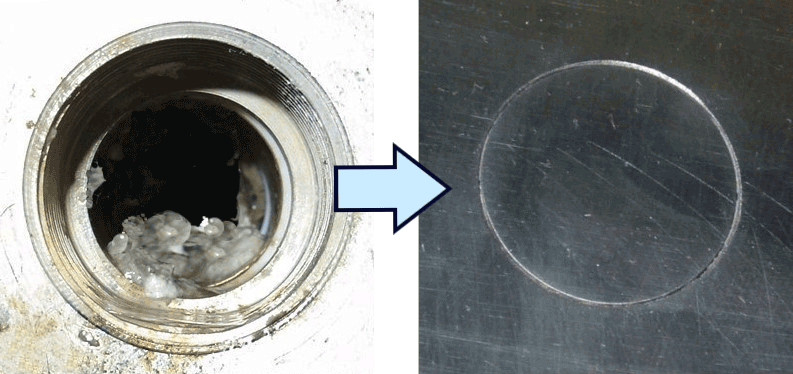

A blind pocket of an unused small inlet or outlet connection or just a simple sampling valve can be full of old stock, dirt and biological activity. It is a probable cause of daily web breaks. Unused connections can be removed using Wetend’s Web Break Eliminators – simple flush-fit sleeve&plug assemblies that completely eliminate blind pockets, improving cleanliness, runnability and end product quality.

Features and Benefits of Web Break Eliminators

Remove unused connections to eliminate web breaks

What causes daily web breaks?

The headbox approach pipe, from the machine screen to the headbox manifold, typically has shut-off sampling valves, unused blind connections, and unused additive dosing connections. A small blind pocket behind the valve often accumulates old stock and deposits with significant biological activity. This pocket frequently releases bursts of dirt and slimy material into the main flow, potentially leading to daily web brakes.

How to avoid them with

Wetend’s Web Break Eliminator

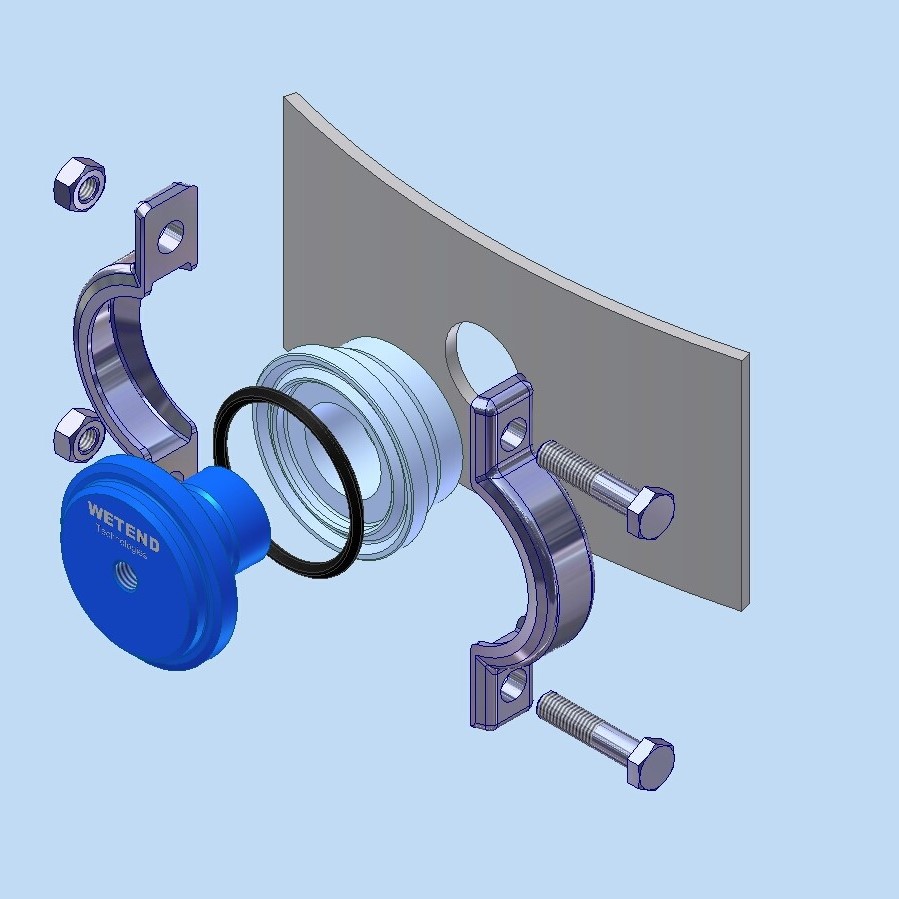

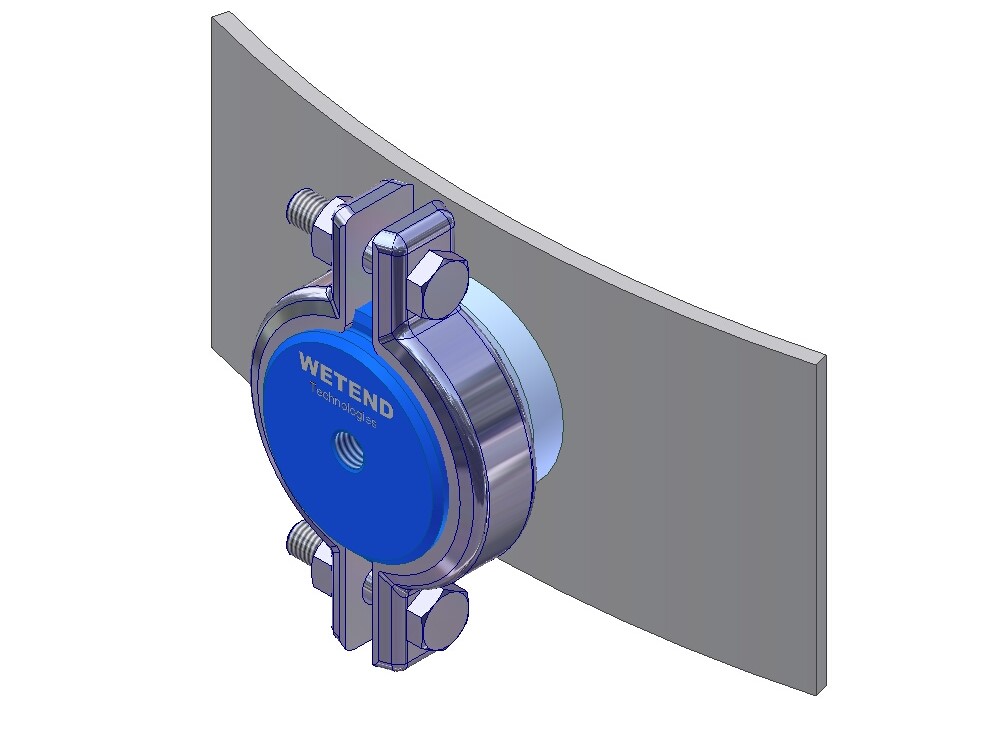

Wetend Technologies has developed a series of tight, polished, flush fit sleeve&plug assemblies to remove blind spots from the approach pipe. Machined to the specific pipe dimensions by order, after installation they are precisely flush with the inner pipe wall, leaving a polished and smooth surface and no potential sources of dirt deposits.

Quick and easy installation

Installation takes from 30 min up to 2 hours, depending on the diameter, and all works are done outside the process pipe. We provide a set of tools specially designed for quick and simple removal of old connections and installation of Web Break Eliminators. It includes specialized hole-saw-drivers by Wetend Technologies that precisely cut the new openings leaving a fine surface and minimizing the need for re-polishing.

Technical details

- Size range: 35-210 mm

- Material: stainless steel

- Finishing: Plug face polished to Ra 0,8 μm, by request to 0,4 μm

- Parts are finalized by order. The pipe outer diameter and wall thickness is required for final manufacturing, as well as the outer weld diameter of the existing connection. Drilling is made outside the weld circle.

Applications

Wetend has supplied close to 2000 sets of flush fit sleeves and plugs. They are usually used to:

- eliminate old process connections

- to install new inlet or outlet valves that can be easily disconnected when needed

- for TrumpJet mixer connections and stock outlet/suction connections

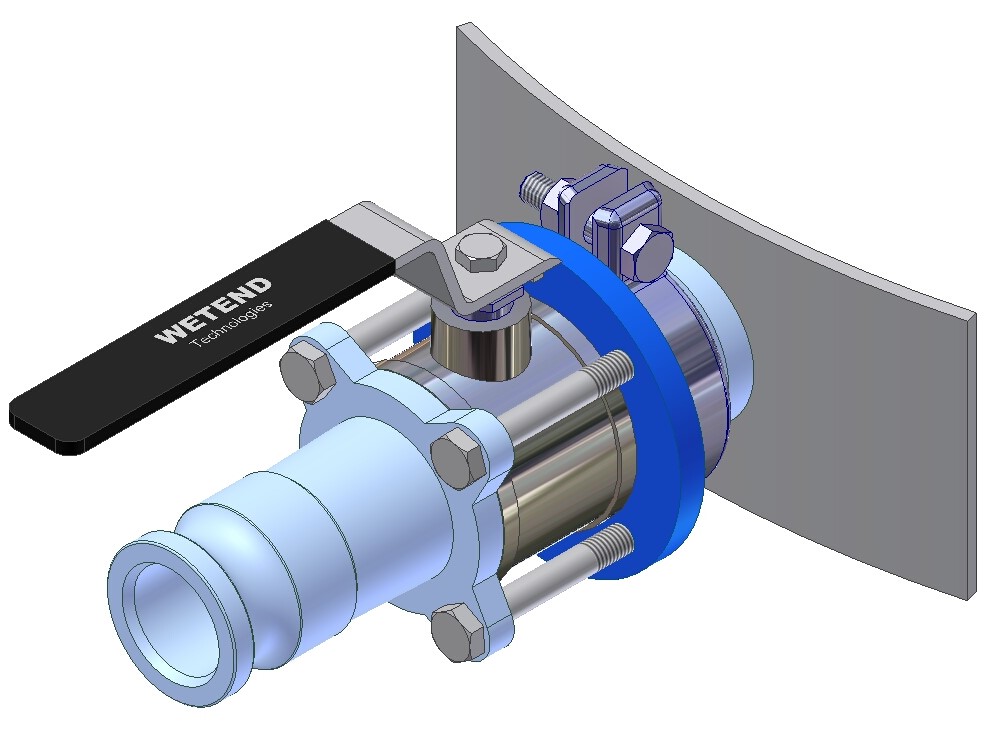

WetValves, if the plugged connection is needed again

If needed, a removed connection can be taken back to service by installing a handy WetValve assembly with optional flush-mounted inlet /outlet valve. Available sizes DN20, 40, 50 or other by special order.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.