Services

Comprehensive services for maximum performance

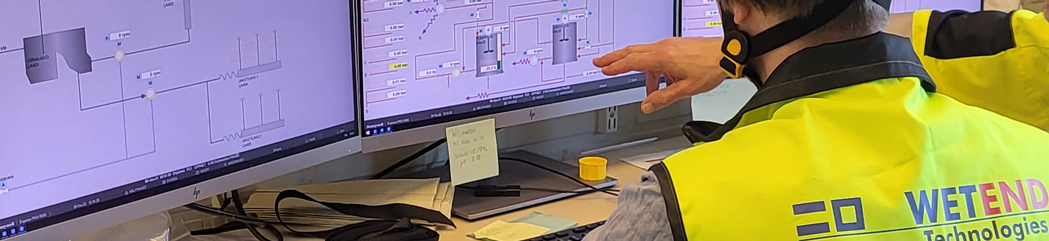

From initial setup to ongoing maintenance and upgrades, we follow up the operation of TrumpJet chemical mixing systems online and on-site to make sure that the equipment works with maximum efficiency, saves resources, and maintain consistent product quality.

Minimum maintenance requirements

Regular maintenance increases the efficiency and lifetime of your chemical mixing equipment. The design of TrumpJet systems enables fast and simple maintenance, which can be done during any of your scheduled shutdowns.

Manage risks and maximize uptime

To ensure that production can continue smoothly, we offer spare unit packages to replace components whose repair might take longer. The spare unit design enables quick and easy disassembly and replacement, minimizing maintenance costs and production down-time.

Three principles in our service offering:

- Maximum equipment performance

- Undisturbed and reliable operation

- Minimum downtime

Want us to handle TrumpJet maintenance for you?

Regular maintenance improves efficiency and lifetime of your chemical mixing equipment. Our expert technicians can take care for that on your behalf. Ask more about our maintenance service options or request a quotation.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.

Up-to-date equipment for best performance

In order to stay competitive, you constantly develop your products and processes, exploiting new raw materials and process chemicals. We are here for you. Through innovation and technological advancements, we constantly improve the efficiency and versatility of our systems, ensuring we provide cutting-edge chemical mixing equipment to our clients.

Our customized upgrades are a cost-effective way for you to keep your equipment up-to-date and optimize its performance so that it best meets your new requirements.

When to consider an upgrade?

Do not hesitate to contact us, if you plan changes in chemistry, process improvements, technology or product development. We will help you to fine-tune your TrumpJet system to the new conditions, and if necessary we will recommend upgrades for maximum efficiency.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.

Auditing of the paper machine chemical system provides valuable information about wet end processes and reveals potential weaknesses and possibilities to improve efficiency, machine runnability and sheet quality.

Points of examination could be: chemical storage and dosing, pumps, flow rates, pipe sizes, pressures and temperatures, possible points of chemical precipitation and dirt pockets, chemical mixing into the main process, headbox area, etc.

After detailed data collection and thorough analysis, our experts prepare a report with a list of recommendable optimizations with prioritization which facilitates more effective planning of future investments.

Mill audit in four steps

- Preliminary questionnaire

- On-site mill inspection

- Data analysis

- Report with recommendations

Searching ways to improve resource-efficiency

or the root causes for persistent quality or runnability issues?

The chemical system is a small part of the paper machine, but it has a large impact on overall performance and a direct influence over process stability, machine runnability and product characteristics. Let our experts have a look.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.

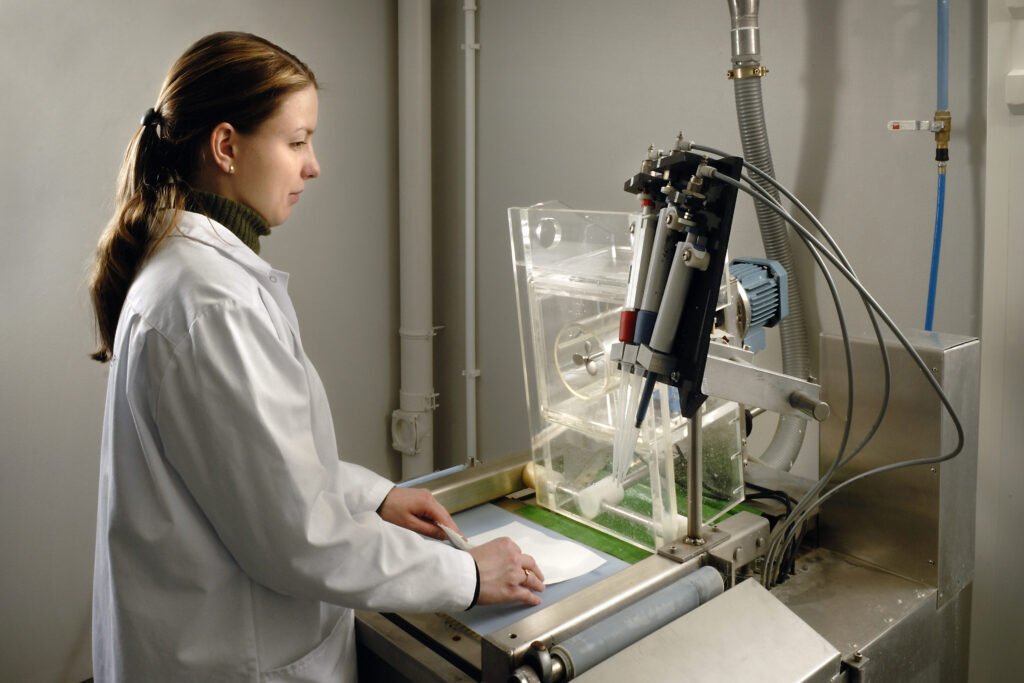

Laboratory services with full scale equipment and devices

Wetend Technologies offers support in planning and conducting lab-, pilot- and factory-scale test runs and analyses, equipment tests, mixing tests, problem-solving, and others. We work in close cooperation with the FiberLaboratory of South-Eastern Finland University of Applied Sciences.

For more information please contact us at sales@wetend.com.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.