Excellent mill results with a single TrumpJet station

Fine paper line in North America, production: 230,000 tons/a

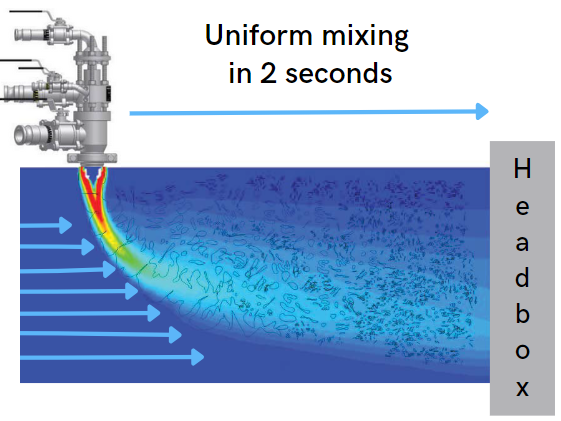

A single TrumpJet Flash Mixing station was installed on the headbox feed pipe, between the screen and the headbox feed manifold.

From this point, the furnish takes an average of just three (3) seconds to reach the slice opening. In practice, this means there are only three seconds for the fibers and chemicals to interact before sheet formation begins.

This is possible because the TrumpJet completes the mixing almost instantly — in less than one (1) second — an extremely short initial mixing time.

TrumpJet mixing station mixes RETENTION AID POLYMER and SILICA NANO-PARTICLE simultaneously into the stock flow.

After the installation:

- Polymer consumption dropped approximately 40%

- Nanoparticle saving approximately 60%, still with a bit higher retention

- Starch volume of ASA sizing emulsion came down by 15%

- Fresh water use for chemical post-dilution was completely eliminated

- Sheet formation improved greatly

- The process responded immediately to the TrumpJet Flash Mixing, and after making the adjustments above, it stabilized and delivered good results.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.